Have you ever gawked at an electric vehicle zipping by smoothly and quietly, wondering what kind of alien technology powers it? Well, dust off your flux capacitors because we’re about to delve deep into the engine bay of these futuristic rides. Hold onto your socket wrenches as we go part-to-part, scrutinizing the high-tech components that help your eco-friendly chariot conquer the asphalt – no gasoline required. Welcome to what I like to call, ‘The Amazing World of Torque and Electrons.’ Buckle up, folks!

The Electric Motor

Diving into the heart of the electric vehicle, we find its pulse – the electric motor. Unlike the internal combustion engines typically found in traditional gas-guzzling cars, the electric motor operates on a process that’s as straightforward as it’s revolutionary. Electricity from the battery creates a magnetic field which then propels the motor, spinning the wheels, and off you go, edging on the very frontier of motoring technology.

Now, we’re talking about two varieties of electric motors here: the Permanent Magnet Synchronous Motor (PMSM) and the Induction Motor. Automakers have their favorites. The PMSM, for instance, is a darling with its high power density, high torque to inertial ratio, and impressive efficiency. It’s the powerhouse under the hood of many a high-performance EV. Tesla, though, fancies the resilient Induction Motor, primarily for its robustness and its capacity to churn out top-drawer performance without an ounce of rare earth material.

Want to know what’s even cooler about electric motors? Instant torque. Yes, you heard that right. Unlike gasoline counterparts which need to build up speed gradually, electric motors supply torque all at once. Picture it like unleashing an eager greyhound in a race – the thrill of making a speedy 0 to 60 mph exit when the stoplight turns green.

While we’re on the topic of pep, it’d be unfair not to mention the quietness of it all. No revving, growling or rumbling. Instead, you get a smooth acceleration that’s accompanied by a whisper-like hum. And while some nay-sayers may miss the vehicular cacophony often associated with power, many enjoy the calmness one can only associate with gliding around in a nifty UFO.

The electric motor stands as a sublime testament to the adage ‘less is more’. Fewer moving parts mean fewer breaks, leading to lower maintenance costs and a longer life-span. Bordering on mechanical minimalism, you could say. In essence, the electric motor represents a certain kind of poetry: few words, massive impact.

In this realm of high-voltage horsepowers and pin-dropping performances, we have met our automotive titan: the electric motor. It doesn’t burn dinosaurs, and it doesn’t ask for much. It delivers speed in silence, with efficiency and elegance, making it a pivotal part of what makes an EV not just tick, but glide into the future. Next up, we’ll discuss where all this power gets stored – in the battery systems.

Battery Systems

Battery Systems truly are the heart and soul of an electric vehicle’s power unit. Without this electrical powerhouse, an EV is nothing more than an exorbitantly priced, minimalist piece of parking lot décor. So, let’s break down that electrifying heart and see how it keeps the motor humming.

First, it helps to think of the EV battery not as one singular entity, but more like a sizeable pack of many smaller batteries, all cooperating to provide juice for your standalone electric motor. Despite the individuality of these smaller cells, they have one prime directive: collectively store, distribute and manage electricity to power your EV.

You might essentially think of them as a phalanx of electrical soldiers, each one standing firm, steadfast, ready to discharge their power upon command. You’ll find most EV battery systems lined-up in the form of Lithium-ion (that’s right, akin to your groovy smartphone), offering the best density, longevity, and recharge-efficiency, putting the old lead-acid batteries to shame.

Now, let’s investigate the sheer capacity of these battery systems. In electric vehicles, the capacity is measured in kilowatt-hours (kWh), a term that could either imply the maximum instantaneous power or the total energy that the battery pack can dole out. Meanwhile, while you may rejoice at a higher kWh number boasting greater-range and power, be wary! The greater power comes with an insulated energy wallop on the price-tag, and a heavier burden on your vehicle’s scales.

But of course, putting power in is only half of the romance, as retrieving that power is a whole different ball game. This is where the crucial term ‘C-Rate’ jumps into the picture. Defined as the charge or discharge rate of a battery, it essentially translates to how swiftly or languorously a battery pack can dump its energy into the motor.

Finally, remember that managing a group of power-packed individuals is always a challenging task, and that’s precisely what the Battery Management System (BMS) undertakes. From monitoring the status of each individual cell, ensuring smooth electricity distribution, to keeping the temperatures in check, the BMS is your EV’s energy sentinel.

Bottom line? The intricacies of the battery systems are crucial in understanding what drives an electric vehicle. Simply put, it’s the sine qua non, the cornerstone upon which the entire EV experience is built. Without it, the vehicle is just an unfulfilled dream of high-tech mobility. With it, the dream becomes an efficient, high-speed reality. Now, isn’t that electrifying?

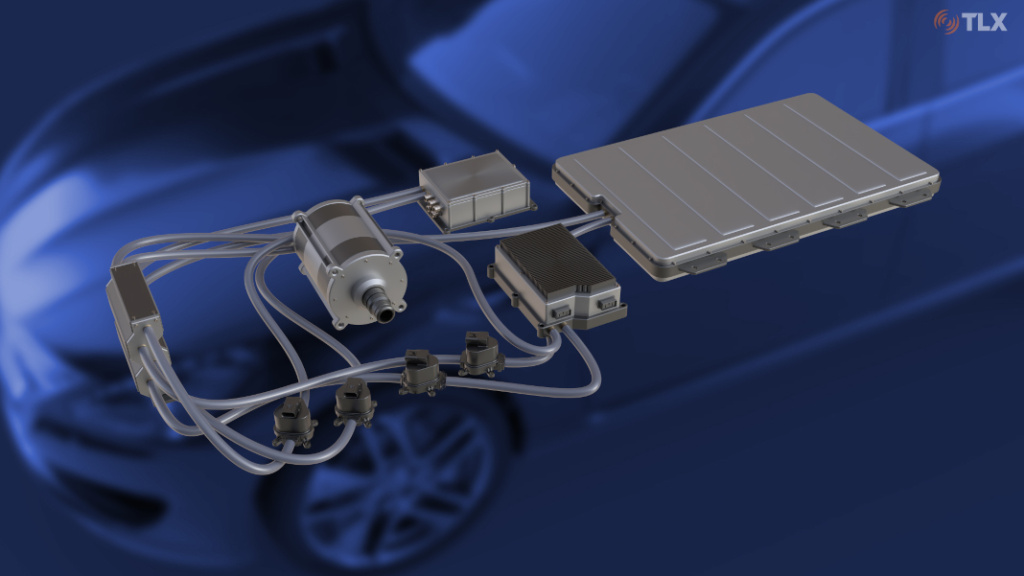

Power Electronics

Harnessing the raw energy of an electric vehicle’s battery system and transforming it into usable power for the whole vehicle requires quite the technological wizardry. And that’s where Power Electronics step into play, functioning as the potent Harry Potter wand that ensures the magic of smooth and efficient EV performance.

In the most simplified terms, Power Electronics function as the middleman in the functionality of an electric vehicle’s system. These crucial components manage and control the flow of electricity between the battery and the electric motor, converting DC power from the battery into AC power that the electric motor can use, and vice versa. It’s like a high-stakes game of tetris where the Power Electronics are responsible for fitting together the right pieces at the right time – kind of complex to comprehend, but fascinating when you see the results in action.

One of the essential components of Power Electronics is the inverter. It converts the DC electricity stored in the battery into the AC power the motor needs to run. Every time you push down the accelerator, you can thank the inverter for ensuring your motor gets the right amount of power in useable form.

Then there’s the converter that swoops in to manage all those usable leftover electrons. When your motor is operating below peak power or during regenerative braking, the inverter shuffles excess energy back to the battery. The converter regulates this return of the electrical energy, knocking down the voltage to a level the battery can safely handle. Like a successful bouncer at the hottest club in town, the converter keeps things under control by managing the influx and preventing any unpleasant overloads.

Just as significant, power electronics control the Air Conditioning (AC) and the Heating, Ventilation, and Air Conditioning (HVAC) systems. Beyond managing your car’s ‘climate’, they recuperate any excess heating generated which can be repurposed, managing energy in a way that is a pure testament to efficiency.

Keeping power electronics in tip-top shape is critical for an EV’s overall performance. It’s not an exaggeration to say that power electronics is the nerve center of an electric vehicle, efficiently and effectively managing the energy flow that keeps the car moving. Without these components, the spectacular show that is an electric vehicle would grind to a boring halt. Let’s hear it for the unsung heroes, power electronics, championing underneath every EV hood.

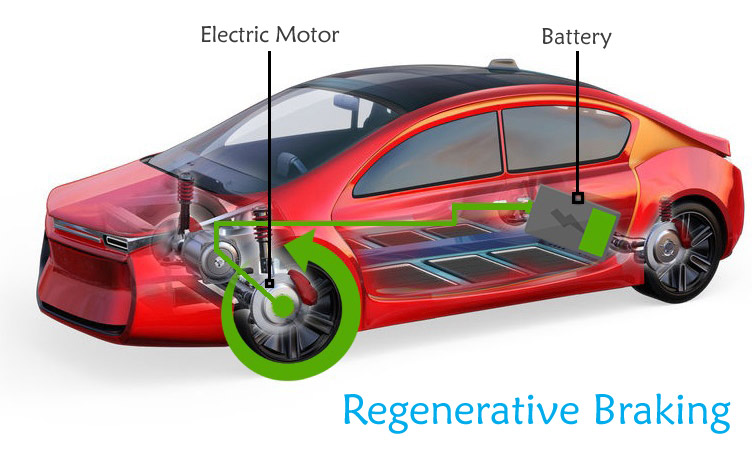

Regenerative Braking System

In the uncanny universe of electric vehicles, the conjuring act of friction isn’t an undesired by-product of attempting to slow a car down; it’s a veritable magic trick of efficiency. That’s where the regenerative braking system, perhaps the unsung hero of the EV world, steps into the spotlight.

Conventional braking systems generate heaps of kinetic energy as they slow a car, which subsequently crumbles away as wasted thermal energy. Doesn’t make a whole lot of sense, does it? And yet, this is a regrettable daily routine for almost every internal combustion vehicle scooting about the planet.

Conversely, an electric vehicle has an ace up its sleeve with the regenerative braking system. When you tap that brake pedal, what you’re actually doing is telling your vehicle to start reversing its electric motor. The motor, obediently slipping into this doppelgänger mode, begins to function as a generator, gobbling up that would-be-wasted kinetic energy as it slows down your car.

Subsequently, it spits out a nifty charge packed right back into the battery with an enthusiastic, low-energy “ta-da”. Imagine your kinetic energy like an undersize pool of potential that just grew into an ocean of possibilities- captured, reoriented and ready for action. It’s an energy-saving pirouette that transforms waste into recovery and makes Fred Astaire look like an amateur.

However, it doesn’t mean that the conventional brakes are completely obsolete. In instances of sudden braking or when you hit the brakes hard, traditional disc brakes take the reins. It’s kind of like a hybrid dance: mostly free-spirited whirls of energy regeneration coupled with the occasional grounding step of conventional braking.

So, you get a boost to your overall range, a big fat nod to energy efficiency, and a car that’s designed to exploit every opportunity to save energy. In hindsight, it’s a bit like trying to catch your own echo. Except in this case, you actually can. That’s not just good engineering, folks, that’s downright magical. In the realm of EV efficiencies, the regenerative braking system is undeniably a jack of all trades.

Thermal Management System

Believe it or not, even electric vehicles can break a sweat. Day in, day out, they’re generating heat from all that high voltage dancing around. And managing that heat—without guzzling power—is a major balancing act. Thus enters thermal management systems (TMS).

Keeping everything cool is a big deal in a gas guzzler believer’s world, but it’s just as important—if not more so—in an electric car. You can’t just pop open a window to let the heat breeze out. When temperatures flare up beyond what they should be, it can reduce the efficiency and lifespan of components, especially the high-dollar-spender, the battery. And no one likes to replace those meaty things before time’s due.

The TMS monitors the temperature of every crucial component to adjust cooling needs accordingly. The barriers to climate control include not only maintaining a comfy temp within the battery pack and other hardware but also in managing the interior climate for those fashionable tech geeks sitting in the car.

Typically for an electric vehicle, that’s the battery pack being fussed over. Management of its thermal equation is critical because of its inherent sensitivity to temperature changes. Too hot and the chemistry inside gets all fidgety, possibly overcharging, and we all know the destructive potential in that scenario. Flip the coin and in cases of too cold, the battery can underperform, reducing the range and efficiency of the vehicle. In other words, it’s finicky as a cat on a rocking chair.

The whole circus gets even more complex when you realize the TMS doesn’t have the luxury of sapping too much energy from the main battery to do its temperature taming. That would put a hurt on your range, and suddenly, like a cruel twist in a thriller movie, the hero becomes the villain. Instead, innovative systems make use of passive and active cooling strategies, such as liquid coolant systems, air ventilation, and heat exchangers, to keep all temperatures in check.

All to say, this isn’t just climate control, it’s thermal juggling. It’s a web of interconnected sensors, algorithms, and mechatronic components, each playing their part in the real-time thermodynamic ballet that keeps your EV happy, cool, safe, and efficient. Rather artful, when you think about it. So next time you’re cruising on the freeway in your quiet EV, spare a thought for the constant heat hustle happening under the hood!

EV Charging Infrastructure

In the bustling heart of an electric vehicle’s functionality, we’ve peaked under the metaphorical hood to shed light on motor mechanisms, battery banter, and regenerative braking breakthroughs. But, apocalyptic naysayers might ask, how do they charge, and can our somewhat dated power structures handle it? Fear not, electric evangelists, for EV charging infrastructure is not only here, but it is rapidly evolving to meet demand in truly astonishing ways.

We’ve come a long way from the times when fiddling with a home outlet and a frustratingly short cord was the status quo for EV charging. Today, it’s as simple as plugging in your iPhone, but instead of a pocket-sized device, it’s a full-sized automobile! EV charging stations, also known as electric recharging points, charging points, charge points, and ECS, can range from plug types to charging speeds.

The most common sighting is a Level 2 charger, popping up in parking lots, retail hubs, and offices. Pioneering a new era of convenience, these chargers fill your ride while you shop for groceries or crunch numbers at work, leveraging AC power to replenish an average EV in 4 to 6 hours. But to those on longer road escapades, fast-charging stations are the honorary knights in shining armor. Quick as a whip, DC Fast Chargers (Level 3) turn an hours-long replenishing ordeal into a coffee break – adding about 60 to 80 miles of range in as few as 20 minutes.

Public charging stations are becoming as commonplace as gas stations, but the future of EV charging infrastructure zooms beyond standard charging stations alone. Innovations such as wireless charging pads awaiting in your very garage, solar panel charging, and battery swap stations are readying themselves to replenish the roads ahead. Anticipating the growth of EV adoption, large hybrids of renewable energy generation and battery storage units, now known as ‘Energy Hubs,’ are being developed. These hubs, aside from charging EVs, could potentially provide clean energy to the grid during peak demand times.

Of course, an expanding network also calls for behavioral adaptation from drivers. If the primary charge spot is now the home instead of a petrol station, the habitual ‘I’m running on empty’ late-night gas run will be no more than a faint memory. Essentially, charging an EV boils down to what would be the routine act of plugging in your phone for the night—a shift in charging mindset, if you will.

So, for those clamoring about range anxiety or the seeming lack of charging options, the EV infrastructure might be evolving more rapidly than our conversations. While we’re undoubtedly in flux about the future of electric vehicles, one thing’s certain: the charge of change is electrifying.

FAQs

What drives an Electric Vehicle?

Are there different kinds of electric motors?

What about special components?

Conclusion

From battery packs to regenerative braking systems, the components of an electric vehicle combine to create a seamless, efficient, and enjoyable driving experience. Understanding these elements not only amplifies our appreciation for these extraordinary machines but also assists us toward a future of sustainable transportation. With the progress in EV technology, it’s clear – the future is electric, and it’s fascinating under the hood.